2024 Air, Space & Cyber: AI-Informed Logistics and Supply Chains

September 18, 2024

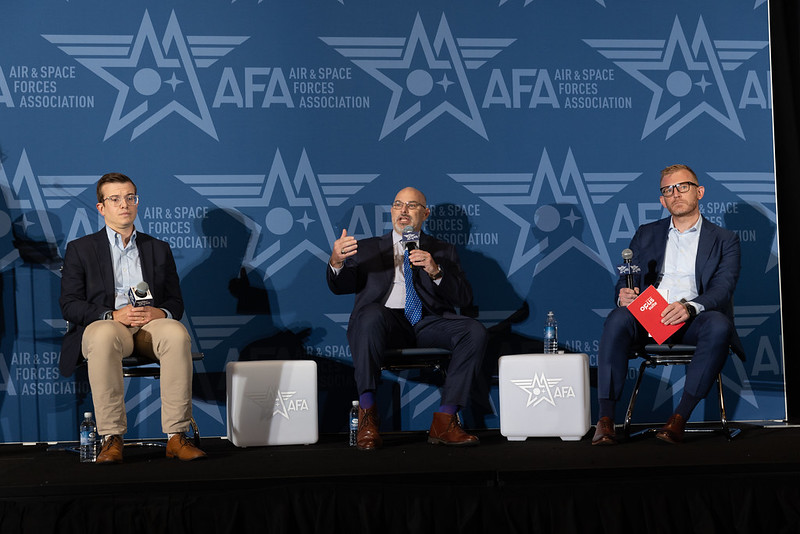

The “AI-Informed Logistics and Supply Chains” session at AFA’s 2024 Air, Space & Cyber Conference featured Matt George, founder and CEO of Merlin Labs; Col. Louis Ruscetta, USAF (Ret.), Virtualitics; and Justin Woulfe, co-founder and chief technology officer of Systecon. The session, held on September 18, was moderated by Chief Master Sgt. Robert Berrier, senior enlisted leader HAF AF/A4. Watch the video below:

Panel Moderator: CMSgt. Rob Berrier, Senior Enlisted Leader HAF AF/AA:

Good morning, ladies and gentlemen. My name’s Chief Master Sergeant Rob Berrier. I’m the Senior Enlisted Leader to Lieutenant General Tom Miller, the Deputy Chief of Staff for Logistics, Engineering, and Force Protection. Before we get started today, I’d like to give a special thanks to the AFA leadership team, our Airmen, our Guardians, allies, partner nations, industry partners, and everyone that was able to make the AFA event this week. Totally understand it’s a heavy lift to all of those competing priorities that we have at home station, so for everyone to make the effort to get out here and see what we have going on for AFA, hugely beneficial to you and, hopefully, your units back home. As previously stated, my name is Chief Berrier, and I have the distinct pleasure of moderating a panel that can only be described as impactful when we talk about support to our warfighters and guardians and airmen across the globe.

Throughout history, warfare has remained relatively constant. The characteristics of war have continually changed. In effort for us to support and better support our airmen around the globe, we, as logisticians, have to evolve as well. Innovation is in our Air Force DNA. It’s no surprise that we continually find new ways to improve and enhance how we conduct Big L logistics and refine supply chains to meet a few strategic objectives along the way. In those specific objectives, we’re talking about ensuring our Air Force is aiming to be AI-ready for a strategic advantage, build strong data in an AI workforce who can design, develop, and deploy AI applications, and advance AI technology that is reliable, ethical, and supports our values as a nation. To accomplish this, we continually tweak and prioritize the improvement of our personnel, resources, and programs. That includes adopting new technologies along the way that can revolutionize how we do business for our warfighters.

On the panel today, I have the honor of sitting with three professionals who are incredibly immersed in finding new ways to innovate, enhance, and create logistical solutions that shape the capabilities of our supply chains using artificial intelligence. We have Mr. Matt George, CEO and Founder of Merlin Labs, Colonel Louis Ruscetta, United States Air Force Retired, Director of United States Air Force Mission Success at Virtualitics, and Mr. Justin Woulfe, Chief Technology Officer and Co-Founder of Systecon. Gentlemen, welcome. I know our audience is excited to hear from everything you guys have to say, so without any other throat clearing, we just get after it. We’re going to jump right in. I guess before we officially start, I’m going to ask each of you to provide a brief introduction, who you are, where you work, and some opening comments to the crowd here today. Mr. George, we’ll start with you.

Matt George, Founder and CEO, Merlin Labs:

Hey, guys. Great to see some familiar faces. It’s okay I didn’t get the introduction of the [inaudible 00:03:05]. It’s early, I forgive you. Great to see you all today. My name’s Matt. I lead up a group of about 150 folks all over the country working on autonomy for fixed-wing aircraft and being able to go deliver trusted autonomy into the force in a way that is stepwise, builds trust, and delivers capability. For those of you in the roo, some of our work that’s relevant to this audience is a work on the KC-135 and C-130J, enabling those platforms to fly more autonomously, but also on the smaller side, some will work on King Air and Cessna Caravans to enable those aircraft to fly uncrewed to be able to go support logistics missions, especially at the edge and in places where we don’t want to send human air crews.

Panel Moderator: CMSgt. Rob Berrier:

Thanks, sir.

Col. Louis Ruscetta, USAF (Ret.), Director, USAF Mission Success, Virtualitics:

Thanks, chief. My name is Louis Ruscetta, for those that don’t know me. Lucky enough to serve 26 years in the Air Force as an acquisition professional and leader. Retired as the B-52 SPO director last year, joined Virtualitics about eight months ago as the director for their air force programs in strategic development, so really excited to work with cutting-edge type technologies like artificial intelligence. Been doing that, lucky enough to do that in most of my career with the Air Force, working with cutting-edge technologies, seeing the importance of what sustainment and logistics brings to the fight. I can tell you as a SPO director, no matter what we were working on from a new capabilities, when something happen in the field that we could not get airplanes off the ground, that was the mission for the SPO director, and to make sure that we were supporting our customer global strike or whomever the match common the user was at that time, to make sure we can still meet the mission. Really excited to be here, thanks.

Panel Moderator: CMSgt. Rob Berrier:

Mr. Woulfe.

Justin Woulfe, Co-Founder and Chief Technology Officer, Systecon:

Yeah, great. Thanks. Good morning, everybody. Always a little unsure about these 8:00 AM sessions. It’s great to have what is a pretty packed house, and I really like to thank everyone for joining us. What I think is a really important discussion on how AI and predictive analytics are really reshaping our supply chains, especially as we think about contested and increasingly complex environments. We’re really facing new challenges in modern warfare. Obviously, contested logistics is a very popular topic, but we also have cyber threats and really rapidly evolving and changing technological advancements. Our military supply chains need to be more resilient, agile, and more efficient than ever before. Gone are days where the static planning and traditional methods could suffice. Our operational environments today demand that we anticipate and respond to threats and disruptions in real time, and I think that’s really where AI and predictive analytics is going to play a really pivotal role.

AI is the power to transform how we manage and optimize our supply chains, with vast amount of data generated across the thousands of potential military operations. Whether it’s asset conditions, mission demands, different kinds of environmental factors, AI is enabling us to analyze this information at unprecedented speed and scale. AI enables us to make smarter decisions, helping to predict potential disruptions, optimize inventory, and allocate our resources much more efficiently. For example, our AI-driven logistics can prioritize supply routes based on real-time battlefield conditions, ensuring that our critical supplies reach the right place at the right time even as we face contested scenarios and degraded environmental conditions. As we think about the application of AI, and predictive logistics, and predictive analytics, we’re going to be able to forecast equipment failures, predict demand for spare parts, and simulate a host of different operational scenarios.

Where supply chains are highly vulnerable, we can help our military planners anticipate risks and mitigate those disruptions before they ever happen. It’s the difference between being reactive and being proactive. It is a shift that can mean the difference between mission success and mission failure. Of course, we’re also facing adversaries that are also using AI themselves and becoming much more sophisticated. Our ability to forecast our supply chain needs and optimize those resources. Using predictive analytics to the maximum extent possible can ensure that we maintain our edge. AI can really enable us to respond to shifting priorities, asymmetric warfare, and cyber threats faster and more effectively than ever. I really look forward to diving into and exploring the challenges and opportunities these technologies present, and discuss their role in maintaining our supply chain dominance in increasingly difficult environments, and look forward to a productive conversation here with the panel today. [inaudible 00:07:51]

Panel Moderator: CMSgt. Rob Berrier:

Jumping right in. Mr. George, we’re going to pick on you since you’re the closest to me. Your company is moving out on some truly groundbreaking efforts that are postured to increase pilot capabilities. Can you talk to how your company integrates human pilot skills into its software and maybe touch on some of the technological advancements that make this possible?

Matt George:

Yeah, totally. One of the things that we think is really important to level set on is just because you have an AI hammer does not mean you should use an AI hammer for every single problem. We’re really focused on three buckets of software in how we’re building the Merlin pilot. The first is highly deterministic software, so very traditional ins equals outs, DAL A, DAL B software to be able to go perform core flight control and core navigation in the aircraft. If the problem is not solvable, deterministically, we then use what we call sniper shot AI skills. Things like natural language, where an air traffic controller can go talk to the system, an air battle manager can go talk to the system, respond to kind of a funny voice but still respond to natural voice.

But things like that are not possible to be able to go solve deterministically, but can be solved in a constrained, machine-learned way. If the problem is not solvable in bucket number one or bucket number two, then and only then do you break out that true, transformer-based AI hammer and be able to enable the system to be a little bit creative, so things like the Sully Sullenberger miracle on the Hudson example of there are no good options and the pilot has to be creative. Taking that all together and then starting to be able to go put that out into real aircraft, but doing so in a way that builds trust and doing so in a way that mirrors how we train and educate human pilots today.

Instead of saying, “Hey, here’s the keys to your KC-135 or here’s the keys to your Cessna 208, pick your aircraft,” we’re putting the system alongside human pilots, essentially sort of the junior pilot, and enabling the human pilot to be able to go monitor or override and be able to go train that pilot and build trust so that we can have some option out in the future about how we go deploy that to be able to go extend human air crews, support human air crews, and do so in a way that ultimately builds trust. Last thing I’ll say on this is it’s been a huge conversation over the past couple days around the so-what problem. I think everybody has now acknowledged that AI and autonomy is an inevitable part of the future of how we project air power, so the question is how do we go from the experimentation stage to how do we actually start to onboard this into the operational force? How do we support against it, how do we train against it, and how do we build warfighter trust in the autonomy?

I think that is an important conversation as we transition from the first stage of admiring the problem, second stage of experimenting with the problem, and now we’re, I think, at a very exciting time, which is starting to think about how we implement the problem. That’s not just a futures thing, that’s not just a MAJCOM thing, that’s not just a COCOM thing. That’s throughout the force, the A-3s, the A-5s, the 8s. Everyone has to be involved in thinking about what the future of autonomy looks like and how to be able to go responsibly on-ramp that in a crawl-walk-run, crawl-walk-fly, pick your poison, way to be able to go deliver that capability to the warfighter.

Panel Moderator: CMSgt. Rob Berrier:

Awesome. Thank you much. That’s a ton of information, sir. Great. Next question, we’re going to run down the line. Mr. Woulfe, you’re up next. A lot of your work’s been related to predictive analytics, and systems, and logistics slash cost optimization. In your opinion, what are the keys to ensuring accuracy and reliability of data used by AI systems and supply chain management?

Justin Woulfe:

Yeah. I mean, I think we all know that inside of our maintenance systems, and supply systems, and ERP solutions, there’s a lot of fuzzy information. A maintainer closes out a work order so they can go home for the day. How long did it take them to do that work? If we’re going to calculate Ao, we need to understand how long the aircraft was down for. If we’re going to predict Ao, we need to have some basis to predict that. Of course, the quality of that data is very important. There have been, over the years, various attempts to modernize some of our legacy MRO solutions, and ERP solutions, and supply solutions with varying degrees of success. But I think as we look to use that AI hammer, we say, “Hey, well, we can just supply AI and get better large language models and natural language processing out of these legacy solutions.” But the reality is there’s not a lot of maybe value in some of the data fields that are in there, so being able to understand them in a more automated way doesn’t help.

I like your talk there on applying deterministic things first. You don’t just apply the AI hammer, and I think there are a lot of things we can do to our core data systems to make them more modern. I think there’s some great lessons to be learned, frankly, with what the Navy’s done, and NAVSEA and NAVAIR both, in modernizing their IT portfolio to be able to apply AI principles and things in a much better way, not just trying to throw AI on top of some of the legacy solutions that exist in some very old school IT systems that are holding us back, frankly. I think there’s a lot to be thought about and a lot to be considered in just the IT modernization side of things before we go try to apply a lot of technology on top of something that’s quite dated.

Panel Moderator: CMSgt. Rob Berrier:

Thanks, Mr. Woulfe. I did have one question. Full disclosure, not related to anything I passed on previously, but as we talk about data and analytics, any thoughts on outsider threats or threats to analytics and the information that we use to develop our AI or the systems in place? [inaudible 00:13:49]

Justin Woulfe:

Yeah. Well, I think auditability is going to be really key. You have to understand how a decision’s made, where our training datasets are coming from. Of course, [inaudible 00:14:02], you could probably have a five-hour or whole PhD thesis, frankly, on that particular topic. There’s so much to unpack there as we think about the threat injection opportunity of training models with deliberately obscured or deliberately bad data. What that means, if you saw the Gemini rollout, and not to pick on Google, but when they first came out, they were training it off of Reddit. Some of the solutions that were being recommended or answers to questions were wild because of the insane stuff that anybody can write on Reddit. When you look at that, if you apply that in the military sense, if a bad actor is injecting those kinds of things into our models, finds a way to do that, then you run a risk without an audit trail and without some traceability of training your models in a poor way.

Panel Moderator: CMSgt. Rob Berrier:

Awesome. Thank you, sir. Appreciate it. Colonel Ruscetta, this next one’s for you. For those that have the chance to review your bio or know you personally, which seems to be a lot of people in here today, it’s evident that you’ve got a lot of depth and breadth when it comes to logistics and supply chains. In your current capacity, what challenges have you encountered in implementing AI and military logistics, and then how did you address any of those challenges or communicate those challenges?

Col. Louis Ruscetta, USAF (Ret.):

Thanks, chief. You love the question on how can we all do better. I think the Air Force has, and actually just the DOD in general, has done a great job just pushing out innovation type of activities. AI is one of them, but it’s still in pretty small steps. Because of that, we see a lot of stove pipeness across this within the community, especially within the maintenance and sustainment logistics community. A lot of examples of where you’ve got MAJCOM’s pushing things out to the field level maintainers. I know the supply chain is working on things within their aspect to look at it. Depots have been looking at it, but how do you see and utilize that across the entire weapons system? Each of those play a very critical part, but when we look at the sustainment ecosystem and how do we go and really optimize all of our resources, especially in a time for great power competition as we look at agile combat employment.

This is where this plays I think a really critical role in not just the sustainment of making sure we can get aircraft flying for its mission, but what do I need to bring into a theater? Especially in a contested environment, we’re going to have to be really careful on parts selection to make sure we bring only what’s needed because of the challenges going in there. As we start moving forward, and again, there are pockets that are taking huge steps, it’s that understanding is from an industry side too, we’ve got to make sure that what we do can interact and interface with all these other type of capabilities. I don’t think there’s going to be one ring that rules them all. It’s going to be a teaming of this across this logistic enterprise to make sure that we can do it in a way that does not hamper it, make sure that everything is much more efficient across the board.

Panel Moderator: CMSgt. Rob Berrier:

Awesome, thank you. Now, we’ll move to, again, a series of questions for the entire panel. Again, feel free to just let it rip as we’ve got. We’re about at the halfway point, so really interested to see what you all have to say for the next few questions we have to coming up. Through the early dialogue, we discussed a little bit about the as-is attributes of AI and where we stand with military logistics and supply chains as far as security and implementation, but this question’s more about the to-be. What future trends or opportunities do all of you see as the most impactful for our Air Force and Space Force in relation to future challenges or in relation to great power competition? Again, we can go down the line, or feel free to come up on the comms.

Matt George:

All right, I’ll start. One of the things that we’re most excited about is the ability to be able to go use a common autonomy system across a wide variety of platforms to be able to go gain experience across platforms. If you have an autonomy system that’s able to go see tens of thousands or hundreds of thousands of flight hours, that starts to become really, really, really powerful, especially if that autonomy system is able to be ported in a relatively cost-efficient, easy, and time-efficient way between platforms. One of the things that we’re most excited about is what that opens up in the aperture that opens up for the US Air Force and others around being able to go use aircraft that we might not traditionally have used, especially in the great power competition, particularly around things like using aircraft that are mothballed or aircraft that are in the boneyard, to be able to go take those aircraft and be able to go deploy those aircraft in pretty interesting ways to both serve logistics, refueling, and tactical missions.

If we force our enemies and we force our counterparts to be able to go in war game against every single aircraft that we have in the boneyard as the potential autonomous tanker, or autonomous airlifter, or autonomous fighter, that starts to become really interesting and allows us to be able to go project air power in ways that we traditionally might not have done, especially if there’s nobody aboard the aircraft. For instance, in the tanker world, one of the things that we’re starting to think about is if you’re able to go to deploy a tanker far afield of where you would traditionally deploy a tanker and be able to go support jets far outside of the normal range, you traditionally support jets with a man tanker, that starts to become pretty interesting. Uses the aircraft that the taxpayer has already paid for and is able to go deliver true, affordable, treatable mass in a way that we, uniquely, as the United States, have the ability to be able to go project that others don’t.

As soon as we start to look at autonomy and AI not just as a thing to be admired, but start to say, “Hey, how does that open the aperture of how we go project air power, and support the warfighter, and support the pilot?” that becomes an interesting Swiss army knife that can be used in present day operations to make sure that our tanker crews are supported on long missions so that they can take some crew rest, all the way up to the far afield new missions, like being able to go use tankers in new ways. That entire corpus of information, experience, and capability can then start to inform new platforms like NGAS, NGAL, and NGAD as we look to the future of building airplanes around autonomy versus building autonomy around airplanes and being able to go define what the next 50 years air power looks like for the United States.

If we develop autonomy in a way that’s flexible, in a way that supports the warfighter and is able to go support things both now in the midterm and the long term in a continuous way, we think that’s really powerful and something that we’re really excited about.

Col. Louis Ruscetta, USAF (Ret.):

I’d say, for me, I’m excited about where I believe AI comes in and machine learning comes in, is the ability to start getting ahead of the problem and being proactive, especially in logistics sustainment world. Every MDS has a story and every aircraft unit has a story of aircraft breaking before it actually gets to its location and the mission. But to be able to start understanding, not necessarily we do a great job knowing what our top maintenance drivers are, what are our top parts drivers, and we’ve got plans against them, but what’s the next thing that’s going to happen? What’s the next item that’s going to break? That’s hard, because old iron fails in new ways. We said that in the B-52 world all the time, but there’s tons of data there to help us understand that. With the data analytics, with the ability to…

Visualization of that data as well to start beginning to see, “Hey, here is my biggest changes over the last month, over the last three months in parts,” in how these things are operating and failing in different ways to now start doing sustaining engineering actions to get ahead of that, because the answer cannot be just go buy more parts. That solves supportability issues, but it doesn’t solve reliability issues, so using AI to help solve these reliability issues from a parts standpoint. We talk about predictive analytics and predictive maintenance and now doing predictive maintenance, not just on the aircraft itself, but how do we do predictive maintenance to bring that down to the LRU level when those systems go to the OEM for maintenance and everything else, because while a part or a system of that component may test fail and that what gets fixed, it goes back on the field, and if there’s another part that was just about to fail, it doesn’t last as long. It lasts pretty short.

How do we use that opportunity just like we’re doing for aircraft now? With CBM+, and the RSO, and all the different activities, how do we bring that to that next level step? I’m very, very excited about how the community is starting to bring this forward to look at that.

Panel Moderator: CMSgt. Rob Berrier:

Awesome.

Justin Woulfe:

Yeah. I think there’s some really, really awesome potential if we think about what does the next 50 years of air power look like. If we were to go back 50 years ago and ask that same question, I’m not sure that anybody would believe the power that we have at each one of our individual fingertips. I mean, the iPhone was only since 2006, and I think everybody now has that supercomputer in their pocket. Maybe not a pager, but a supercomputer. Yeah. As we think about what this means though, I think there’s so much on the autonomy side from the DARPA Grand Challenge in ’99 where the farthest a vehicle made, it was about 200 feet from the starting line, to now having the idea of pulling tankers out of the boneyard and flying them autonomously entirely without a human. That’s an amazing evolution in 25 years, half of that period.

It’s unfathomable 50 years ago that… Or maybe not unfathomable, but certainly unprobable and certainly impossible at that time. There was a great picture a few days ago of an SR-71, the precursor, the test asset from F-35 and an F-117, all on the tarmac out at Palmdale at Lockheed, and that it kind of encompasses that 50 years of air power in one photo. Now, as we look towards what will the next photo look like in 2050 of what’s on the ramp at Palmdale, it’ll be really interesting, and I think there’s some great things as we think about how do we make these next generation of systems more cost-effective. Of course, we want to have more capability, but I think some of the benefits in the engineering process of applying AI to do some automated testing, to have that digital twin exist, and understand how that thing’s going to perform before we go build something and then have to make a whole bunch of engineering changes that, of course, add dollars to the program and add costs to the program, that digitally fly before you buy ideas, can help us save millions and billions of dollars.

I think the application of AI isn’t just in predictive maintenance or things that are more tactical, like actually flying an airplane, but I think a lot of really strategic things and the whole engineering and staff augmentation on the front side as well can really help us be more efficient, be more effective, and ultimately allow us to procure that next generation of air systems within the budgets that we have available.

Panel Moderator: CMSgt. Rob Berrier:

Awesome, thank you. Great stuff. One of the things that as we talk through the AI piece, and machine learning, and all of these new innovations is that with any paradigm shift, there’s the potential for disruption, and whether that be due to the systems or the human factors in play. Can any of you guys provide any information on what organizations can do to effectively integrate AI into their existing logistics and supply chain operations without causing major disruptions?

Matt George:

Sure. When folks ask us at Merlin what’s the hardest technical problem that we’re facing, I think they often expect some flight control answer, or some collision avoidance answer, some JADC2-related answer, but the answer I always give is human factors. The hardest part of what we’re dealing with is human factors. In order to actually be able to go deploy autonomy, what we have to do is get that alongside a human, building trust with that human. But as we’ve seen throughout the past 10 years at aerospace, the combination of machine and human is not straightforward, especially as the AI system and the autonomy system starts to gain more and more authority over the airplane. How can we do that in a way that is responsible and how can we do that in a way where the human is able to elegantly transition from in the loop, on the loop, off the loop?

If we try to jump to off the loop, Matt George’s opinion, I think we’re going to have a huge reckoning and we’re not going to get to where we want to go as both industry and as the air force. We’ve got to take the slower, more deliberate first downs, move the chains approach of transitioning the human from very much in the loop on the autonomy, to carefully on the loop, to off the loop. For those of you who are pilots, who are trained pilots, when you first get in an aircraft with somebody else who has not flown with you before or that you don’t necessarily trust completely, your hand is really tight on that stick, and then you gradually relax to the point where you trust the other pilot in the flight deck with you. That’s how we have to approach autonomy. If anybody doesn’t recognize the importance of human factors, I think we end up moving much slower as an industry.

Col. Louis Ruscetta, USAF (Ret.):

Yeah. On my side, I’ll tell you my thoughts through this has been AI has been a great decision support tool. If I bring it back into the sustainment and logistics side of it is how do we use that for decision support? Because in the end, the human needs to be in the loop. Those maintainers, those supply chain reps, they’re on the hook. They’re the commanders in the field that are making the decision that have that authority and responsibility, so they need to understand what are those information that’s being fed into those tools so they can actually make that decision. Because in my mind, at least from a support standpoint, there are so many different things that are outside of the data that are important that play into those decisions as well, so that maintainer or commander needs to understand what is all going on, so making sure to bringing that in from a decision support aspect to ensure that.

Again, it gets back to building that trust. Because if we’re going to build that trust with that user and that user believes, “Hey, AI is not going to cause this toaster to come kill me in the middle of the night,” that they can understand that what this does is actually bring support to the user and to the warfighter from that aspect.

Panel Moderator: CMSgt. Rob Berrier:

Awesome.

Justin Woulfe:

Yeah. I think it’s really important that all the senior leaders and aspiring senior leaders in the room really look to embrace some of the new methods, and capabilities, and tools that are out there. The adage of “this is the way we’ve always done it, so this is the way we’re going to continue to do it”, I think, is still very pervasive today across the force. If you have a innovative capability and innovative solution, regardless of where that sits, but I think particularly in logistics and supply chain, I think there’s, of course, a need to validate and verify anything before we go roll out something new across the enterprise.

But there’s some really, really exciting, really interesting things out there that are really promising, frankly, but are running up against a lot of roadblocks that I’ve personally witnessed as it comes to, well, we’ve always done it this other way, and we know intuitively that that’s not working well and certainly won’t support us as we move into a new space. But there’s still a reluctance to do anything differently, and I think that’s something that we’ve got to chop its head off immediately. I think that falls on the senior leaders to help push out some of these new capabilities and new things in a way that is, of course, responsible but also embracing innovation.

Panel Moderator: CMSgt. Rob Berrier:

Great. One of the things I think helps smooth some of this stuff over is that proven principles and case studies where we’ve had success with AI. As we’re getting running towards the end of our time, would any of you care to share any real world examples, whether we’re talking industry, or military, or somewhere where we’ve crossed the mix where we’ve had some legitimate success stories that you all have been a part of or you all have witnessed firsthand?

Matt George:

Yeah. I’ll bring a corollary in from the autonomous driving world, where autonomous cars have been really, really difficult to be able to go integrate into really complex cities and things like that. They’re getting there. For anybody who’s been in San Francisco, or Phoenix, Arizona, or any one of those test cities in the past couple months, you’ve seen a wide variety of autonomous cars truly driving driverless out instead of the streets, but the thing I actually think is most interesting is autonomous trucking. It’s a much more constrained problem, especially on the interstate, and is able to go deliver real results a little bit more quickly. Once again, making sure that we’re not admiring the highest end part of the problem and focusing on where we can move the chains and get first downs along the journey, even if that’s not the shiniest problem.

Col. Louis Ruscetta, USAF (Ret.):

I think we got to give kudos to what’s been done out there. I know the Rapid Sustainment Office has done a lot of good things when it comes to AI. They’ve moved that forward. People can discuss on how it’s doing for particular platforms and things like that. But from a big picture, that is definitely moving forward and has actually changed the landscape. Lucky enough, so our company’s been working with Air Force Global Strike Command for the last couple of years, putting an AI tool that has been used by the A4 community now getting pushed out fairly soon to the tactical units out at the bomber and ICBM wing level for maintainers to use. It’s because of what they’ve been able to see and utilize things not just from… This is where you optimize all of the resources together, whether it’s your parts, your supply chain, support equipment, personnel, bringing that aspect together along with different activities from a, “Hey, how do I select the right tails to go on a deployment for a BTF?” for example.

Utilizing all that information to, again, decision support, make some of those strategic level decisions or operational level decisions “what do I bring forward to make sure I’ve got the biggest operational mission success during that timeframe?”, as well as down to the tactical level of how do I optimize a maintenance plan to attack for the next week or two weeks that we can load resources against. I think that stuff is going on right now, and it’s just moving that forward at a pace that is not necessarily risk averse. We’ve got to make sure we’re taking some risk, challenging the entire environment as we move forward.

Panel Moderator: CMSgt. Rob Berrier:

I fully agree, sir.

Justin Woulfe:

I think on the augmented assistance side towards some of our planners, we’ve seen some really great things with Boeing and with AMC, magic on there as they apply and develop risk kits and do some of their analytics on the Boeing side with F-18, and then in support of the Navy in Australia, and then obviously with AMC with the C-17 and KC-135s where you take the time it takes. Even if you get the same answer at the end of the day, if you’re simulating the many different courses of action and different war-gaming scenarios to develop a risk kit that meets your probability to successful mission, or Ao requirements, or Am requirements, if you can take that time from weeks or months and turn it into hours, that gives analysts more time to be effective, and question the results, and validate data, and do the analyst’s job rather than waiting for the brute force simulation models to run.

Applying AI and that idea of what does that mean for the enterprise of things that took weeks now take hours, if you apply that to more cases, you’re talking about thousands and thousands of man-years saved on the planning side.

Panel Moderator: CMSgt. Rob Berrier:

No, and I agree. I think from the logistic side of the house is we’re not just talking about efficiency to get things to the warfighter. We’re talking about being responsive and being good stewards of taxpayer dollars. Ultimately, this helps what all of those things look like. Outstanding, great stuff. As logisticians, I know we got plenty of them in the room, we’re getting down to that less than five-minute mark so we always want to stay on time. As we’re getting close to wrapping this panel up, I’d ask the panelists just one last opportunity to share any closing remarks for the crowd and any thoughts on the way ahead for what we’re looking like for AI, and logistics, and supply chain management.

Matt George:

Don’t forget, this stuff is fun, guys. I think if you look back in history, the people that we identify as being in the room when there was a big shift never knew that they were in the room when they were in the room. We had the dawn of the propage at the start of World War II where we transitioned from very, very basic stuff to a true facsimile of what modern air power looked like. We had the dawn of the jet age. We had the dawn of the modern jet age about being able to go take that stuff and actually deploy the air force in the commercial world that we see today, and I think this is the room. I think this is the time. This is the group of people, everyone from the maintainers, to the planners, to the folks in the industry, to the pilots.

We’re looking back 50 years from now, this is the time, this is the group, these are the people, like them or not, where we’re going to really be able to look back and say, “This is the group of people that brought the next 50 years forward and started the autonomous age of flight.” That’s a huge privilege, and it’s fun. We have to do it responsibly, and we have to do it in a way that is ultimately supportive of the warfighter. But I think that’s a huge privilege, and I think it’s a tremendous opportunity that we, on the industry side and the Air Force, has to be able to go define what the next 50, 100 years of aviation looks like. I’m really proud to be part of it with all of you. Thanks. [inaudible 00:37:05]

Col. Louis Ruscetta, USAF (Ret.):

GPC is a tough, wicked problem set, and us, as a country, are being asked to go and execute and succeed in that mission, especially within the Air Force, with a fleet of aircraft that’s getting older every single day. In order to succeed in that, it’s really going to be on the backs of our sustaining and logistics community to ensure that that happens. I truly believe that whether it’s the maintainer in the field, whether it’s our folks running the supply chain and depots, or our acquirers looking at the sustaining engineering aspect to make sure we can keep this operational running, this mission going forward. The ability to optimize the resources, in order to do that, because let’s be honest, it’s not like we’re throwing an extra pile of money to go and solve this. Everything, all of our resources, whether it’s funding, whether it’s people, whether it’s assets, are all very constrained.

Using tools to optimize those resources to move forward, to execute a very, very demanding mission, it’s going to be challenging, but one that, as we start taking steps forward and looking at and starting to execute, is going to have great benefit. I do really, from the bottom of my heart, applaud everybody that’s here that is working on that problem set, and there’s not one answer. There’s multiple different answers. It’s how do we go and integrate those answers to find that solution going forward, that integrates a bunch of different capabilities, a bunch of different products to solve what I would argue is probably the most wicked problem we’re going to face as a country over the next 15 years.

Panel Moderator: CMSgt. Rob Berrier:

Mr. Woulfe.

Justin Woulfe:

Yeah. I mean, look, the fact that there’s so many of you in here at 8:00 in the morning, that braved the weather, and the traffic, and everything else to listen to this and listen to us give our thoughts on this, is, I think, testament to the importance of the topic. As we think about in that next 50 years of air power and how we can sustain that, how we can maintain that level of capability, how we can do so within the relatively small budget that have applied towards modernizing our capability. It’s, I think, very important for everyone here to be as innovative as possible to apply that next piece of what looks to be a promising technology and carry that forward. I applaud all of you all for braving the weather and being here today with us, so thank you.

Panel Moderator: CMSgt. Rob Berrier:

Awesome.

This transcript was auto-generated, and may not be 100 percent accurate. The source audio and video can be accessed above.